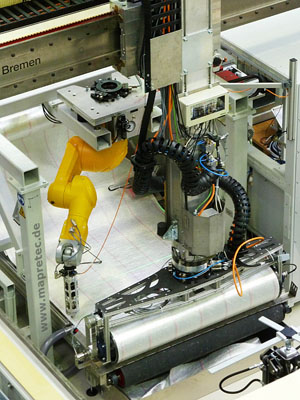

To make production more appropriate for the material, economical and energy-efficient, integrated automated processes are developed and tested at the Handling Competence Center. These processes range from the material supply of the technical textiles through to final rotor blade assembly. The main focus is on the technologically complex issues associated with the handling of flexible materials for the production of fiber-reinforced composites. This is enabled by combining intelligent, flexible automation technology, adaptive material handling and innovative sensor and information technology.

TECHNICAL DATA

- Effectors for textile gripping

- Effectors for binder application

- Effectors for 2D and 3D quality measurement

- Ultrasonic cutting system

- Material supply unit for textile rolls up to: 80 kg and 50” in width

- Flexible preforming unit for large parts

- Blade mold: root/transition section 6 x 3 m, M5000

Industrial robot

- Stäubli TX90

- Velocity up to 1m/s

- Acceleration up to 2 m/s

- 8000 x 6000 x 1200 mm

- Velocity up to 2 m/s

- Acceleration up to 2 m/s

- 5000 x 4000 x 1200 mm

- Velocity up to 1 m/s

- Acceleration up to 4 m/s

- Max. test load 100 kN

CONTACT

Institute for Integrated Product Development, ForWind – University of Bremen

This email address is being protected from spambots. You need JavaScript enabled to view it.